The Penfeeder is an automatic system for laser marking cylindrical components. Patented for pens, it can adapt to different types of parts, perfect for when you need to respond to large production volumes

By submitting this form you accept ours normative privacy.

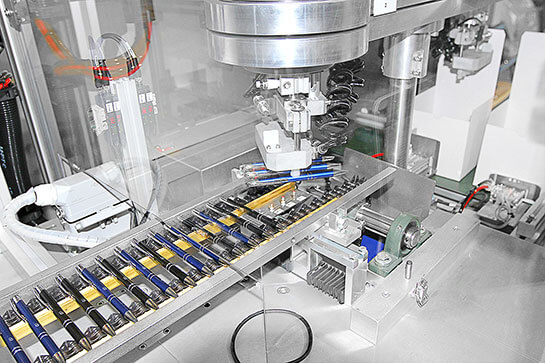

The operator’s job is reduced to a minimum thanks to the complete automation of the system. In fact, after the pens are loaded into the magazine in a disorderly manner, the Penfeeder independently ensures their orderly positioning on the chains by means of specially designed V-shaped fins.

The Lift and Rotation system then moves the pens in order to align the clips, guaranteeing the precision of work and time optimization in the next step.

The Marking and Rotation system allows for automatic 360° rotation of the pens, moving them so as to mark all around the circumference.

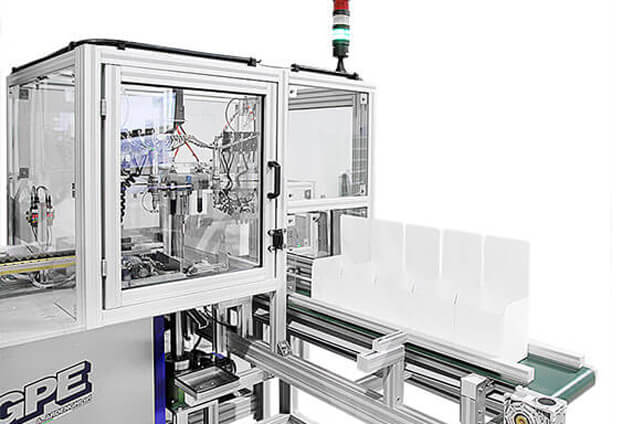

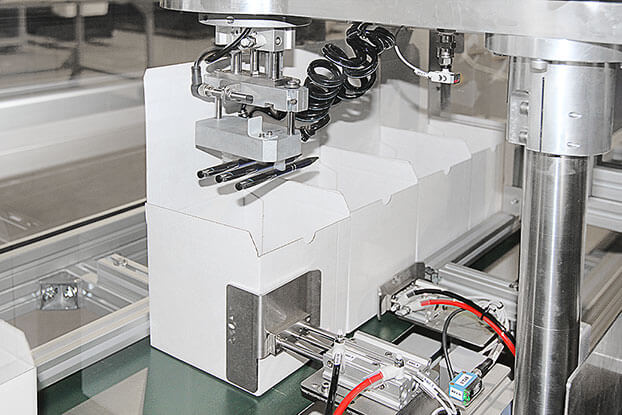

With the orderly unloading system designed by LASIT, it is also possible to manage the storage of pens in boxes, specifically thanks to the Pick&Place system which, after marking, takes the pens and rotates them to optimize the capacity of the boxes.

The software is used to set the number of pens per box. The pens move neatly on the belt up to the storage position. A sensor detects the presence after every three boxes filled and they are pushed onto a mobile carriage. The operator only removes the trolley after nine boxes have been collected.

With the integration of a second, same type of laser, we are able to mark twice as many components, going from 1800 to 3600 pieces per hour.

With the integration of a second, different type of laser, however, we can use the Penfeeder for marking totally different material components, optimizing production with an integrated system for multiple applications.

Did you like this article?

Share it on

LASIT Sistemi e Tecnologie Elettrottiche S.p.A.

Via Solferino 4

80058 – Torre Annunziata (NA)

P.Iva 02747991210

C.F 01803670643

Copyright © 2024